Explosive Failure of Vessels

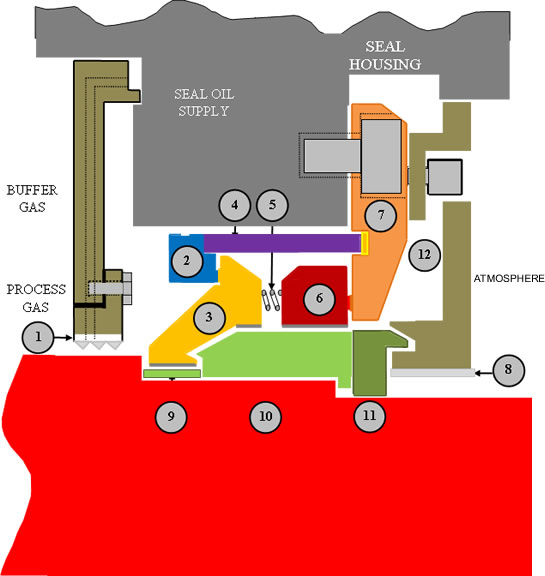

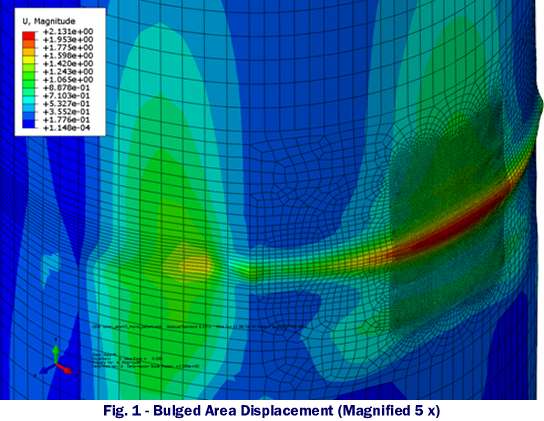

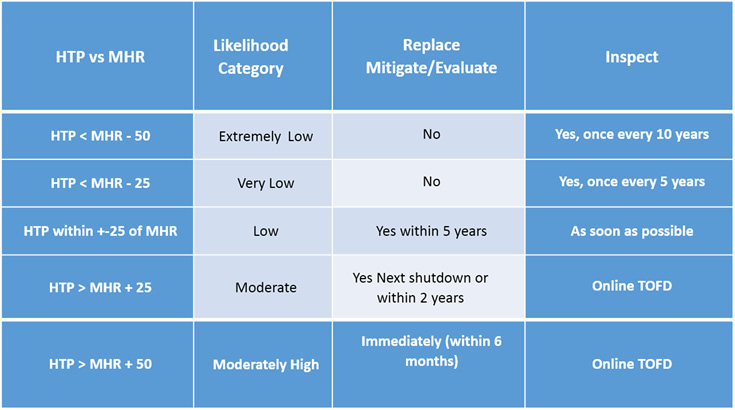

FAILURE MODE – When an explosion (either a subsonic deflagration, or a supersonic detonation) occurs in a metallic vessel, one of three things can happen: Case 1 – Containment: The vessel can contain the explosion, elastically as if nothing happened, or with plastic bulging. Case 2 – Rupture: The vessel can rupture, without ejecting fragments. […]