Becht Conducts HTHA and Crack-like Flaw Assessment for Reactor

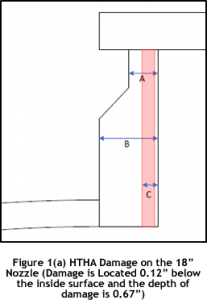

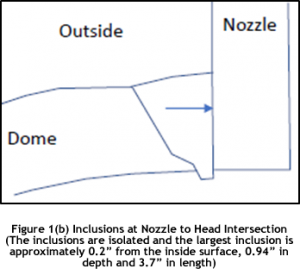

During turnaround inspection of a Reactor, High Temperature Hydrogen Attack (HTHA) damage was found on the 18” nozzle and the inclusion/planar flaw was found on the 18” nozzle to head weld. Figures 1(a) and (b) show the locations of these flaws. Figures 1(a) and (b) show the locations of these flaws.

Besides these two flaws, an inclusion/planar flaw was also found at the head to shell weld. This inclusion was 0.2” from the inside surface, 0.12” in depth and 9.3” in length.

Besides these two flaws, an inclusion/planar flaw was also found at the head to shell weld. This inclusion was 0.2” from the inside surface, 0.12” in depth and 9.3” in length.

Becht was contacted to conduct the analysis of the HTHA damage and used some of the following in its methodology:

- Modeling the 18” nozzle to head intersection using 3-D finite elements

- Use 80% of the yield stress and ultimate tensile stress to generate the elastic plastic material model for the analysis per Part 7 API 579/ASME FFS-1 Level 3 procedure

- Application of internal pressure and nozzle loads with a load factor

- Conservative estimation for the loads since nozzle loads were unknown, we will use

- Solving the model with non-linear geometry effects

- Utilization of the same finite element model with only elastic properties and analyzing the model with design pressure and nozzle loads

- Assuming the HTHA damage as a crack like flaw and evaluate using the procedures per Part 9 in API 579-1/ASME FFS-1

Becht provided a detailed report and presentation for the client, and delivered its conclusions that were among the following:

- The inclusions/planar flaws found at the nozzle to shell weld and at the head to shell weld were analyzed as crack-like flaws per API 579-1/ASMEFFS-1 and they were found to be fit for service.

- The HTHA damage found in the nozzle was analyzed as hydrogen damage and cracklike flaw per API 579-1/ASME FFS-1 and it was found to be fit for service.

- At the operating conditions, the C-0.5Mo material was found to be susceptible to HTHA. There are no published methods for performing a FFS assessment on known HTHA damage. The approach used here demonstrates the vessel was safe to operate in the current damaged state.

- Eventual replacement of the reactor within 3-5 years is recommended with an inherently resistant HTHA material, such as 1.25Cr or 2.25Cr alloy steel.

- Prior to replacement, follow-up HTHA inspection should occur on a 6 to 9-month interval to assess any growth of the HTHA damage. If growth greater than 20% of the original depth of damage has occurred, re-evaluation of the FFS should be performed.

- Additional recommendations and analysis was provided

Please see our broad range of capabilities at Becht Services

Do you have a question about this article or wish to contact one of our experts? Contact Us