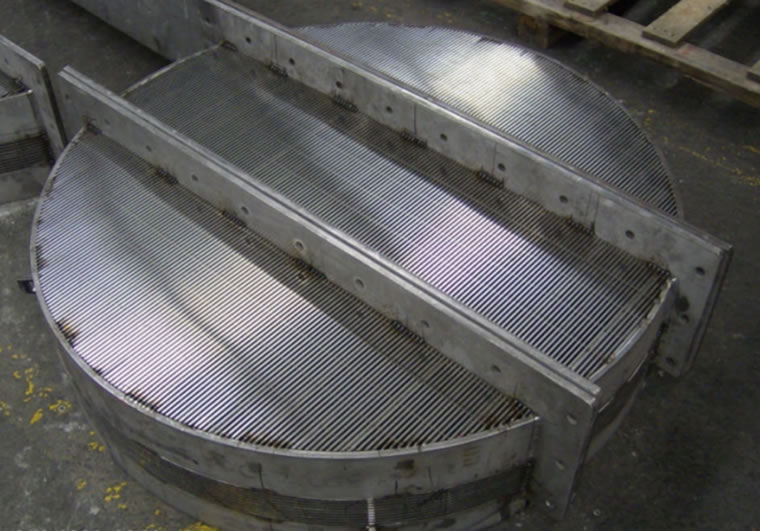

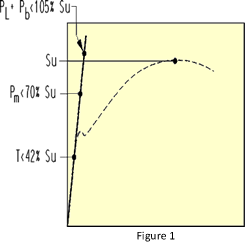

Outlet Collector Pressure-Drop Assessment

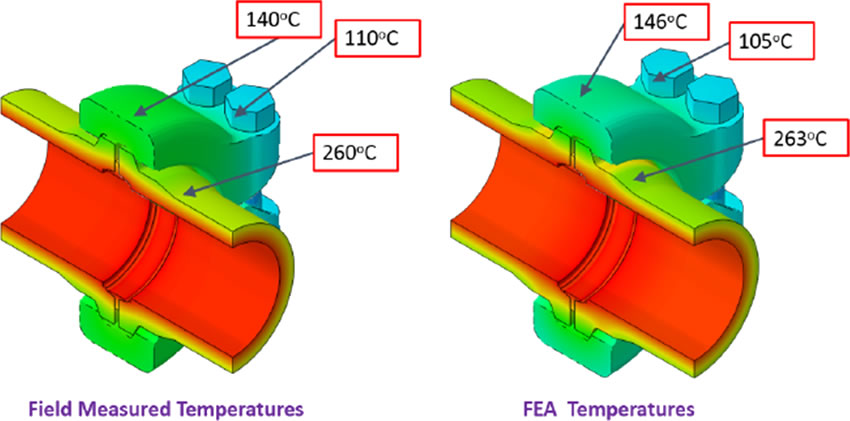

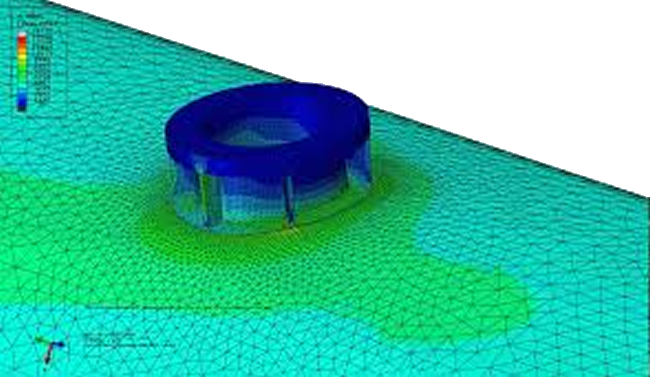

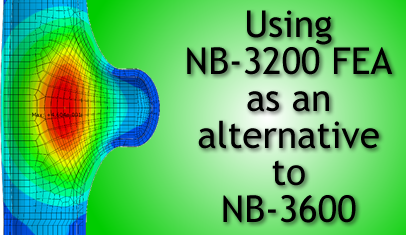

Why do outlet collectors only rarely fail, even when subjected to pressure-drops well above the design basis of the collector? The answer lies in the design approach which incorporates simplifying assumptions to accommodate a tractable and conservative approach. These conservatisms can be relaxed where necessary to give results much more in line with actual experience […]