In-Structure Response Spectra

Currently there are nearly 100 commercial nuclear power plants operating in the US with most of the plants commissioned between the mid 1960’s and the mid 1980’s. All plants are designed to be capable of safely withstanding a postulated earthquake, known as the safe shutdown earthquake. Similar requirements are imposed on US Department of Energy (DOE) nuclear processing facilities. In addition to the structures themselves, it must be demonstrated that safety-related equipment such as pumps, valves, instrumentation, and electrical components can remain functional after, and in some cases during, the postulated earthquake. This article addresses various ways of demonstrating qualification of safety-related equipment and components – that is seismic qualification of equipment and components, with particular emphasis on generating the required input motion for seismic qualification by testing.

Seismic qualification of components remains an important issue not only for new facilities, but also for the aging nuclear fleet. As the fleet ages, safety-related replacement parts for the existing facilities must be seismically qualified and fewer vendors than in the past are providing pre-qualified equipment, so the burden often falls on the owner of the plant or facility to perform the seismic qualification.

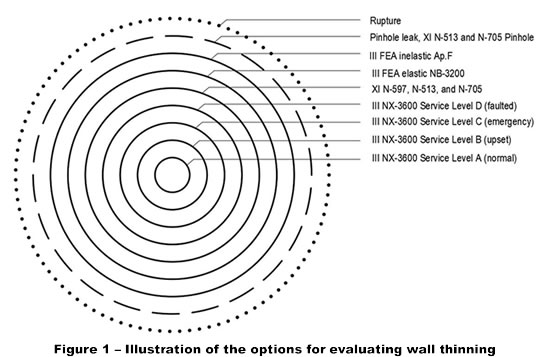

Seismic qualification is demonstrated via four basic methods; analysis, test, experience data, or similarity (or a combination of these four methods). If seismic qualification is to be demonstrated by test, the equipment or components are mounted on a shake table and subjected to a representative seismic motion. A key question then becomes “how is the appropriate input motion established?”

The input motion to the shake table test must represent the motion that the in-service equipment or components will see at the mounting point on the shake table, and the tested equipment must be in a configuration on the table that represents the in-service configuration. A common situation is when the seismic input at the base of the structure that houses the equipment is known, but the seismic input at the mounting point of the equipment or component is unknown. These two seismic motions can be quite different because the structure housing the equipment or component typically acts to amplify the motion and shift the frequencies at which the peak accelerations occur. That is, the mounting point input typically has higher peak spectral accelerations then the base input motion, and they occur at different frequencies.

In this case, the required input at the mounting point is established by analysis through the use of a structural model that transmits the base motion through the structure and produces the seismic motion at the mounting point of the equipment or component. The seismic motion can be extracted as set of time series or as response spectra, which are known as in-structure response spectra (ISRS). When providing input to shake table testing, the mounting point motions are most often extracted as acceleration ISRS.

The acceleration ISRS represent the required input motion to the shake table test and are called the required response spectra or RRS. The test facility takes the RRS as a requirement and generates a set of acceleration time series used to drive the shake table. The sufficiency of the acceleration time series used to drive the table is verified by converting the time series back to their corresponding response spectra and comparing these spectra to the RRS. The response spectra resulting from the table input motions are the test response spectra, or TRS. The TRS must envelop the RRS over the frequency range for which the test is designed. In some cases, the TRS must exceed the RRS by a specific factor to account for multimode effects or to assure that certain performance goals are met. Further details for equipment qualification are addressed in ASME QME-1 for active mechanical equipment, IEEE 344 for safety-related electrical equipment, and ASCE 43 for seismic design criteria for nuclear facilities.

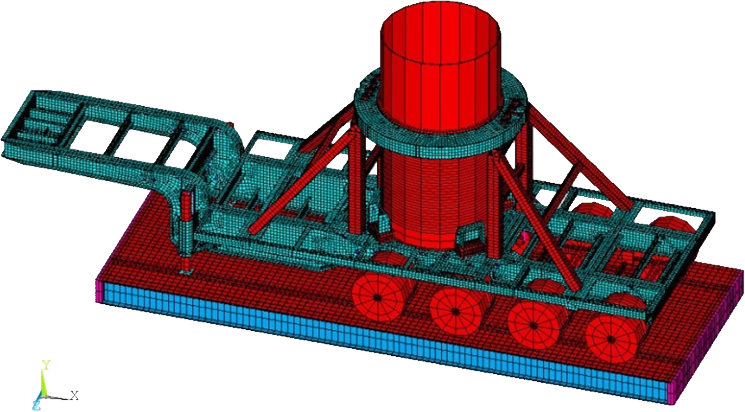

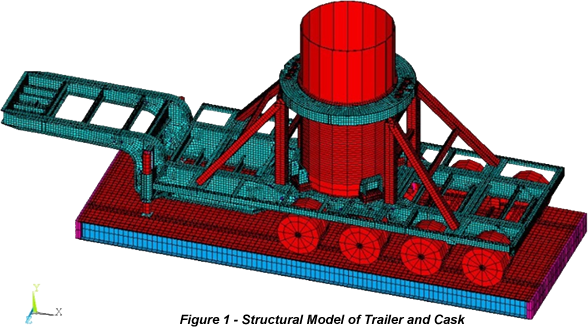

An example of a structural model used to extract ISRS is shown in Figure 1 below. It represents a cask sitting on a trailer in a nuclear facility. The motion of the ground on which the trailer rests is known and the goal is to determine the seismic input at the top of the cask, which is the mounting point for mechanical components and instrumentation to be tested on a shake table.

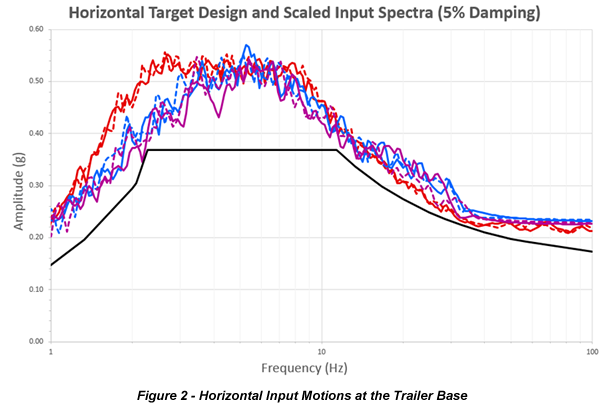

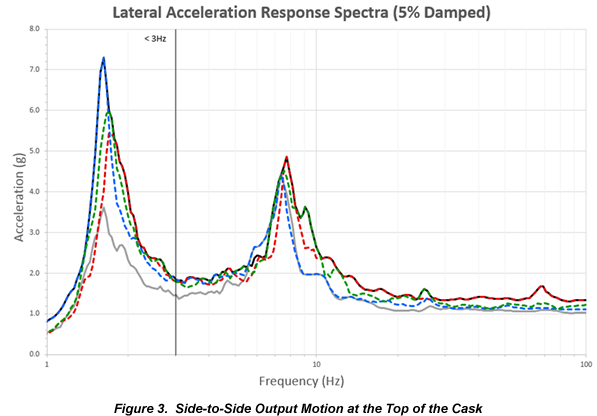

The horizontal input motion at the trailer base is shown in Figure 2. Note that the peak horizontal accelerations at the trailer base are approximately 0.55g. The side-to-side accelerations at the top of the cask that is mounted on the trailer are shown in Figure 3. It is clear that the trailer system not only acts to amplify the input motions, but also acts to dramatically change the character of the motion, indicating the importance of the structural model in determining the ISRS.

This example illustrates the importance of developing the correct ISRS for the seismic qualification of equipment attached to a structure, to reflect the amplification and frequency shift of the seismic input motion as it is filtered through the supporting structure.

Have a question or would like more information? You may post to this blog or click the link below for more help.

[readon2 url=”https://bechtwp.com/index.php?option=com_rsform&view=rsform&formId=4&Itemid=739&lang=en”]Request Info[/readon2]

Can the in-structure response spectra be obtained without performing a time history analysis? Is it possible to obtain the in-structure response spectra from response spectrum analysis itself?

If time history analysis is used, then how do you obtain acceleration time history?