Piping Settlement Screening Tool

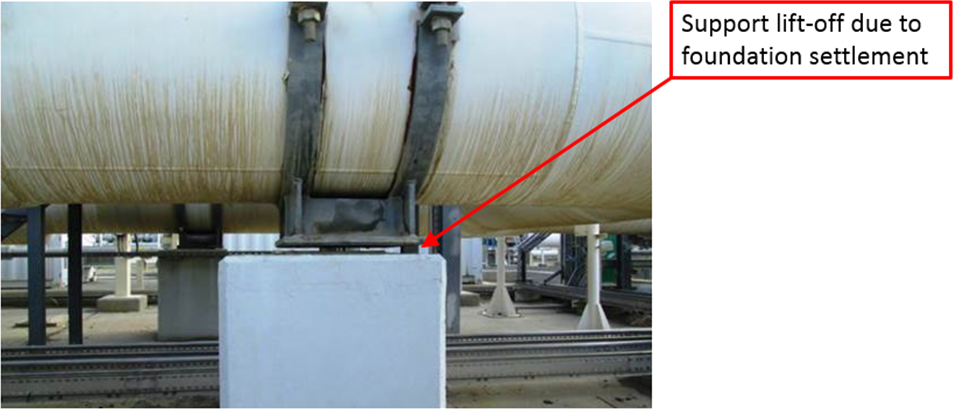

Settlement of a pipe support foundation is usually not a big deal to assess. A local piping flexibility model will reveal if the settled support keeps the pipe bending stresses within the allowable codes and, if the bending stresses are unacceptable, modifying the support and monitor periodically for further settlement is normally a quite manageable […]