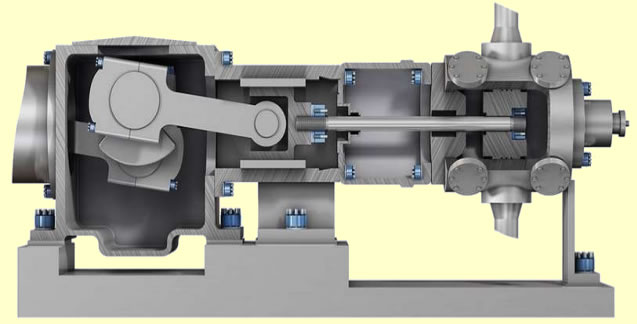

Reciprocating Compressor Cylinder Alignment (Often overlooked as a failure root-cause)

Compressor cylinder bore misalignment can cause failures that are often not attributed to misalignment. Crosshead shoes uneven wear, compressor piston rod failure at both the crosshead and at the piston, compressor piston rod coating failure, piston wear and compressor cylinder bore wear can all be attributed to cylinder misalignment. The objective of this article is […]