Process Centrifugal Compressor Oil Seals

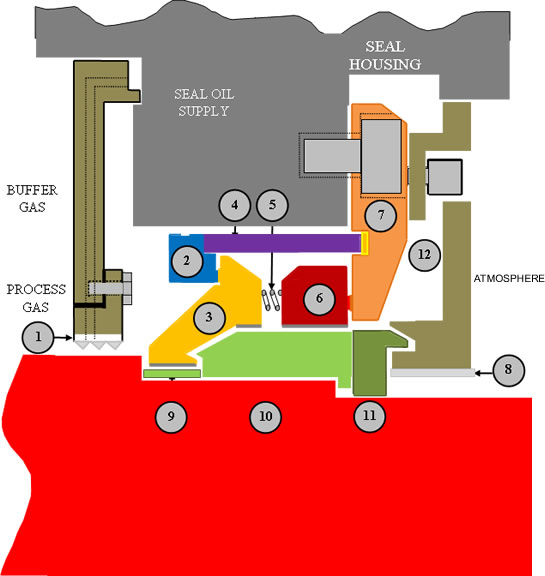

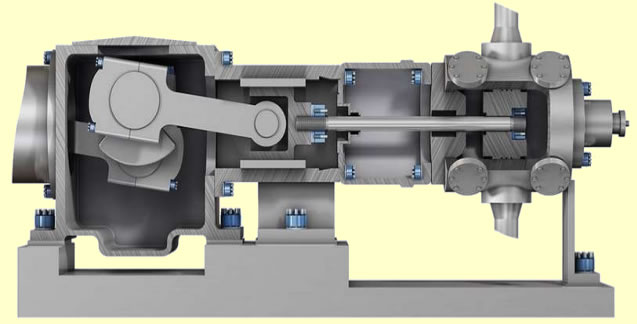

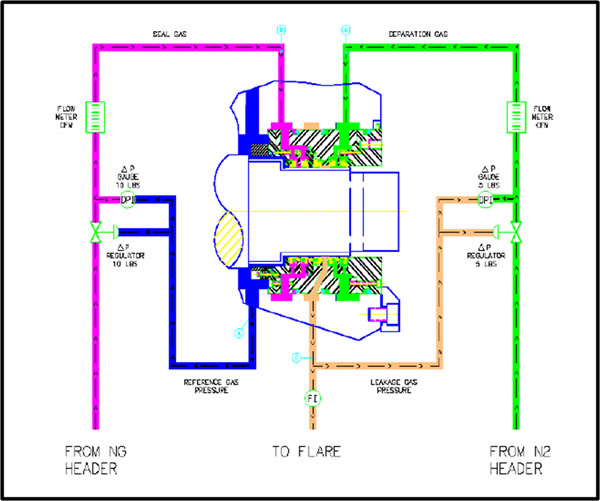

Ingersoll Rand Cone Oil Seals Compressor process shaft end seals are designed to seal the rotating assembly in the stationary compressor case to prevent the process gas in the compressor from escaping to the atmosphere and to prevent the atmosphere from getting into the process gas. Shaft end oil seals, as compared to the relatively […]